In the realm of material purification and separation, efficiency and effectiveness are paramount. Industries dealing with minerals, chemicals, plastics, and recycled materials often face the challenge of removing impurities and enhancing product purity. This is where the Magnetic Roll Separator shines, offering a high-intensity magnetic field to efficiently purify materials.

Understanding Magnetic Roll Separator Technology

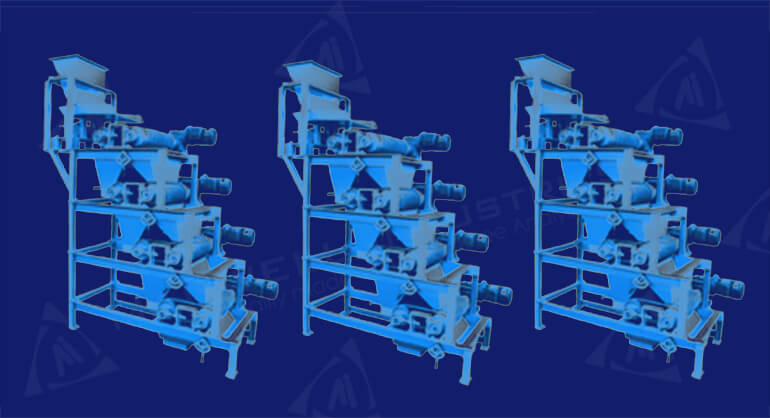

The Magnetic Roll Separator utilizes high-intensity magnets to induce a magnetic field into a roll-type separator. This field attracts and retains magnetic particles, separating them from non-magnetic materials. The separator consists of a permanent roll made of NdFeB (Neodymium Iron Boron) disks interleaved with pure iron disks, providing a robust and efficient solution for material purification.

Operating Principle

Material to be treated is fed onto a conveying thin belt by a vibratory feeder. As the material moves along the belt, magnetic particles are attracted to the roll and diverted into a separate chute, while non-magnetic particles continue down the belt. This simple yet effective process ensures the purification of materials with high efficiency.

Key Features and Benefits

- Efficiency: The Magnetic Roll Separator offers a highly efficient solution for purifying materials, ensuring high-quality end products.

- Ease of Operation: Simple operation and maintenance make this separator user-friendly and cost-effective.

- Customization: The separator can be tailored to specific industry requirements, ensuring versatility and adaptability.

- Durability: Constructed with high-quality materials, the Magnetic Roll Separator is built to withstand the rigors of industrial applications.

- Environmentally Friendly: As a permanent magnet, the separator does not require power during operation, reducing energy consumption and environmental impact.

Applications

The Magnetic Roll Separator finds applications across various industries:

- Mining and Mineral Processing: Purification of minerals such as silica, sand, quartz, and feldspar.

- Chemical Industry: Separation of compounds like aluminum oxide, chromite, and emery.

- Recycling Industry: Efficient separation of metals and electronic waste.

- Food and Pharmaceutical Industry: Purification of food products and pharmaceutical materials.

- Plastics Industry: Removal of impurities from precision plastics.

- Ceramics and Glass Industry: Purification of raw materials for ceramics and glass production.

Conclusion

The Magnetic Roll Separator stands as a testament to innovation in material purification technology. Its ability to efficiently separate magnetic and non-magnetic materials has made it a valuable asset in various industries. With its high efficiency, ease of operation, and environmental friendliness, the Magnetic Roll Separator continues to play a crucial role in enhancing material purity and quality.