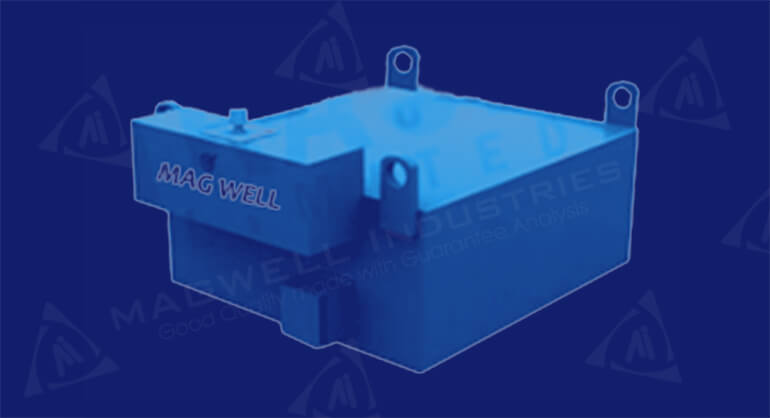

In the world of material processing and purification, the Suspension Magnetic Separator stands out as a powerful and efficient tool. Designed to remove both large and small tramp metal from product streams conveyed by belts, this separator offers a reliable solution for industries seeking to enhance their product purity.

Understanding Suspension Magnetic Separator Technology

The Suspension Magnetic Separator features a powerful magnetic field that attracts and captures ferrous metal contaminants from conveyed materials. It is typically installed over a conveyor belt, where it efficiently removes tramp metal, ensuring the purity of the final product. This separator is available in manual and automatic configurations, offering flexibility to suit different operational requirements.

Operating Principle

As material is conveyed beneath the Suspension Magnetic Separator, any ferrous metal contaminants are attracted to the magnetic field and captured. The captured metal is held on the surface of the separator, while the cleaned material continues along the conveyor belt. The separator’s continuous cleaning mechanism ensures uninterrupted operation and minimal downtime.

Key Features and Benefits

- Effective Tramp Metal Removal: The Suspension Magnetic Separator is highly effective in removing tramp metal from materials carried over conveyors, ensuring product purity.

- Permanent Magnet: The separator utilizes a permanent magnet, eliminating the need for power during operation and reducing energy consumption.

- Easy Installation and Maintenance: Installation of the separator is straightforward, and maintenance requirements are minimal, contributing to cost savings.

- Durable Construction: Built with high-quality materials, the Suspension Magnetic Separator is designed for long-term, reliable operation in industrial environments.

- Versatile Applications: The separator finds applications in a wide range of industries, including recycling, coal, quarrying, ceramics, and food processing, among others.

Applications

The Suspension Magnetic Separator is used in various industries for the removal of tramp metal, including:

- Recycling Industry: Separation of ferrous metals from recycled materials.

- Coal Industry: Removal of tramp metal from coal streams.

- Quarry Industry: Cleaning of aggregates to enhance product quality.

- Ceramics Industry: Purification of raw materials for ceramic production.

- Food Processing Industry: Ensuring the purity of food products by removing metal contaminants.

Conclusion

The Suspension Magnetic Separator is a versatile and efficient tool for enhancing product purity in material processing industries. Its ability to remove tramp metal from conveyed materials ensures a high-quality end product while minimizing the risk of damage to downstream equipment. With its durable construction, ease of installation, and effective tramp metal removal capabilities, the Suspension Magnetic Separator continues to be a valuable asset in various industrial applications.